This 3D printer part is a ticking time bomb—and you need a backup on hand

Summary

The article highlights the critical role of the PTFE tube in 3D printers, emphasizing its potential as a single point of failure. The authors recommend keeping a spare on hand to ensure uninterrupted printing operations.

Key Insights

What is a PTFE tube and why is it critical to 3D printer operation?

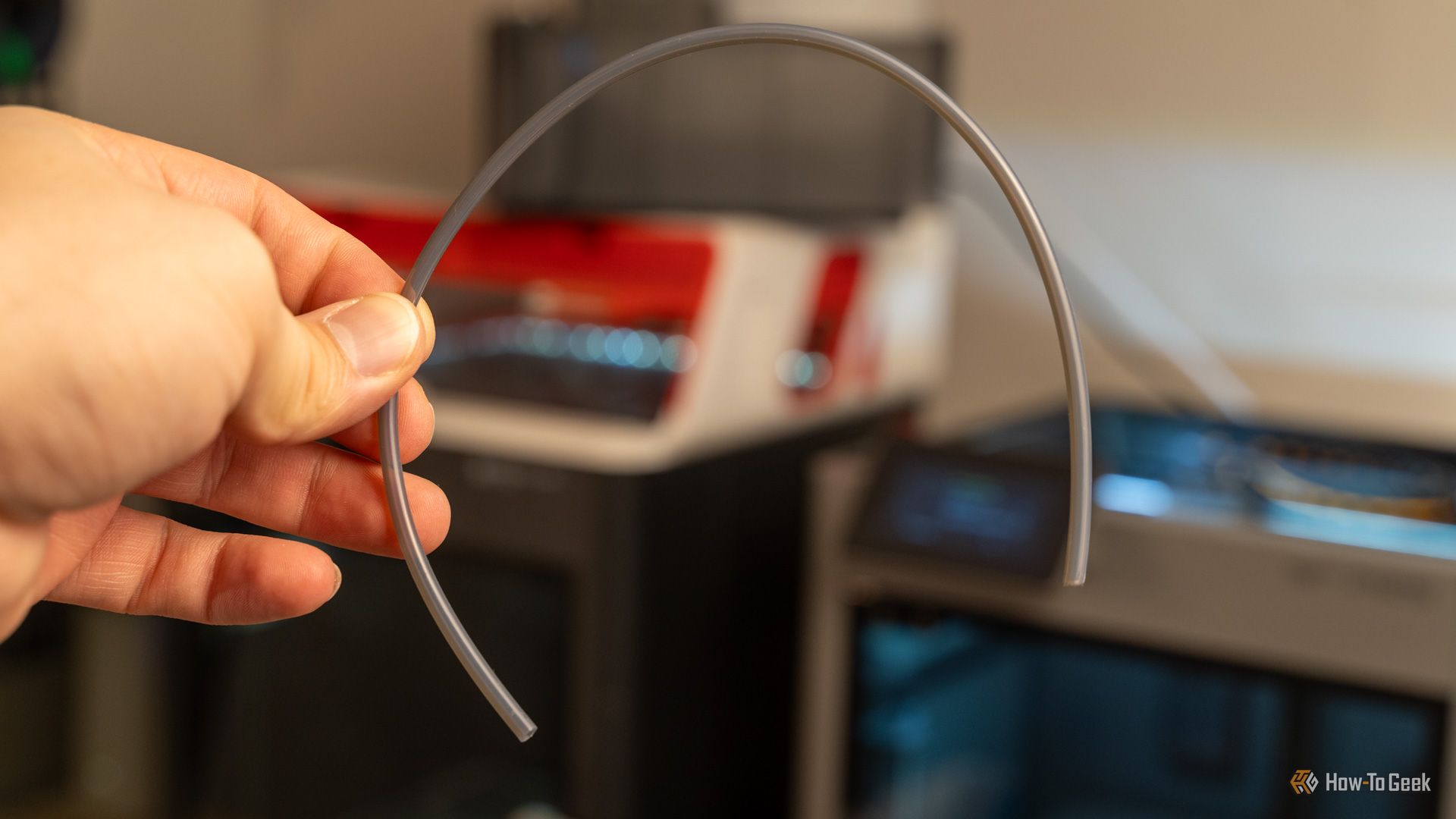

A PTFE tube, also called a Bowden tube, is a hollow conduit that guides filament from the spool to the printer's hot end for melting and extrusion. It is critical because it ensures the filament travels smoothly without encountering obstacles, maintains proper direction, and prevents damage or deformation during transit. The tube's low coefficient of friction (0.04-0.15) allows consistent filament feeding with minimal resistance, which is essential for print quality and reliability.

Why does a PTFE tube degrade over time and what are the signs of failure?

PTFE tubes degrade primarily due to heat exposure. When printing with high-temperature materials like PETG or ABS (requiring 240-260°C or higher), the tip of the PTFE tube becomes extremely hot and can deform slightly, increasing resistance within the tube. This degradation is gradual and can eventually lead to negative print results including inconsistent filament feeding and poor print quality. Standard PTFE tubes are particularly vulnerable to this issue, which is why premium alternatives like Capricorn tubes—designed to withstand higher temperatures—are recommended for demanding applications.